Alpen’s Revolutionary ThinGlass IGU Line: Transforming Window Manufacturing in North America

Our friends at Alpen reached a historic milestone by bringing North America’s first automated ThinGlass IGU (insulated glass unit) manufacturing line into full operation. This groundbreaking achievement represents the culmination of years of strategic planning, investment, and unwavering commitment to making ultra-efficient windows accessible to the broader market.

Strategic Investment and Partnership

This revolutionary manufacturing capability was kickstarted with Alpen securing $18 million in total funding during 2024. This significant financing combined a $5.9 million grant from the Department of Energy (DOE), awarded through the Bipartisan Infrastructure Law and Inflation Reduction Act, with an additional $12.1 million in private capital investment. This public-private partnership is a great example of how government support can dovetail with private innovation, accelerating the deployment of proven technologies.

For five years prior to this investment, Alpen collaborated with the DOE’s national lab system and the General Services Administration (GSA) to pioneer and rigorously test ultra-thin-glass technology as a lightweight insulator in windows. Having validated the technology’s performance, the company was positioned to scale production dramatically.

A Game-Changing Manufacturing Line

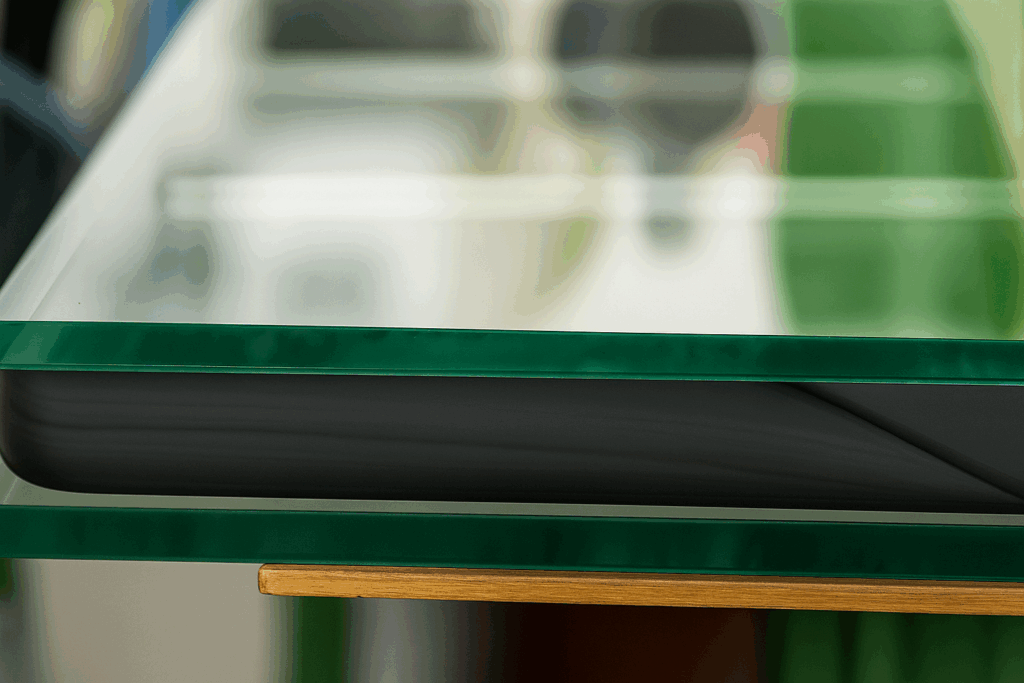

The new automated ThinGlass IGU line represents state-of-the-art manufacturing technology specifically designed to produce Alpen’s innovative thin-glass units with unprecedented efficiency and quality. The automation concepts integrated into this line enable consistent, high-volume production while maintaining the exacting standards required for ultra-efficient window performance.

The line’s capabilities extend beyond simple automation. Advanced quality control systems ensure every IGU meets Alpen’s rigorous specifications, while the manufacturing process accommodates various glass thickness options to serve different performance requirements. These allow Alpen to produce thin-glass units that can be integrated into various window designs.

Alpen ThinGlass offers unparalleled versatility to meet diverse projects. The technology accommodates a wide range of sizes up to 72″ x 108″ and fits standard glass pockets from 3/4″ to 2 1/4″. Alpen ThinGlass delivers exceptional performance options up to R-15, enabling builders to meet today’s most rigorous energy codes and achieve top-of-market efficiency. The product line supports an extensive array of coatings and configurations, including tempered, laminated, impact-resistant, and bird-friendly glass. Alpen ThinGlass can be precisely customized to many performance and design requirements.

Market Impact and Recognition

The significance of this achievement hasn’t gone unnoticed. The Wall Street Journal featured Alpen’s ThinGlass IGU line, highlighting how this first-of-its-kind technology is reshaping the window manufacturing landscape. CEO Andrew Zech articulates the company’s vision clearly: “Alpen’s goal is to scale the advanced window market by manufacturing affordable, ultra-efficient windows and glass right here in the United States.” This mission directly addresses a critical high-cost barrier that has historically prevented widespread adoption of advanced window technology.

Building a Sustainable Future

Beyond manufacturing efficiency, Alpen’s expansion creates meaningful economic opportunities. The company’s growth is generating hundreds of new jobs in American communities impacted by coal plant and coal mine closures, demonstrating how clean energy investments can revitalize regions transitioning away from fossil fuels.

The ThinGlass IGU line forms the foundation of Alpen’s comprehensive product ecosystem, serving as the core technology in their windows and doors. This inclusive approach positions Alpen not just as a product manufacturer, but as a catalyst for elevating building performance standards across the entire sector.

As extreme weather events driven by climate change become increasingly common, the urgency for resilient, energy-efficient building components has never been greater. Curious about Alpen’s ThinGlass IGU line and want to see more, or even tour their facility? Talk to our AE Building Systems team about your options and how to learn more!

Leave a Reply