Let’s start by clearing up a misconception about building envelopes:

Buildings need to breathe, walls don’t.

If you want a building to be energy efficient and comfortable, you can’t have leaky walls. If you want a resilient building without mold issues, you can’t have walls that trap moisture. With a continuous insulation strategy, however, you can have your cake and eat it too.

ASHRAE 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings, defines continuous insulation (CI) as “Insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings.”

Continuous insulation greatly reduces the movement of heat through a building’s walls. Done correctly, CI greatly improves a building’s efficiency and comfort. Not everyone is gung-ho about CI, however, so we’ll address some common concerns.

Objections

One objection to using CI and air sealing is the misguided notion that “Walls need to breathe” to prevent mold and mildew. A CI strategy can indeed cause problems if vapor closed materials are used because they trap moisture. There are instances where this has contributed to mold, rot and indoor air pollution. Let’s be clear about breathing – walls do not need breathe, and instead need to enable moisture to migrate out. This is a fine but very important distinction.

Also, too little CI can fail to move the dew point outside of the wall assembly, which can contribute to similar problems. If the dew point is within the CI layer, the risk of mold formation is much lower. These risks, however, can easily be further reduced, as we’ll discuss shortly.

Strategy and risk mitigation

There are three core elements of a CI strategy:

- Airtightness

- Vapor open materials

- Thickness or total R-value

Generally, you want all three. However, if you have air tight and “thick enough” insulation, vapor open is less important. Likewise, if you have air tight and vapor open, the thickness while impacting thermal performance is not as important related to mold issues. And finally, if you have vapor open and “thick enough”, air tightness is arguably less of an issue. We’ll begin by touching on each element in isolation.

Airtightness: Air tightness can be compared to the zipper on a down jacket. On a mountain top, the down jacket is essentially worthless if the zipper is not zipped. We can easily lose 30 – 40 percent of our homes’ energy through leakage, making airtightness essential to comfort and energy performance. Air sealing is also advisable because leaky walls let air and moisture into the exterior wall assemblies, creating the risk of condensation and mold. An airtight building envelope also improves indoor air quality by preventing allergens like dust, pollen and other contaminants from entering the home.

Again, the idea of constructing an airtight envelope flies in the face of conventional wisdom that “walls need to breathe.” The reasoning is that buildings that don’t leak trap indoor air pollution and excess moisture. This concern, however, is easily addressed with a good mechanical ventilation strategy. Vapor open walls is the key not “leaky” walls. Walls need to be able to dry not “beathe”.

Vapor open materials: Insulation and air sealing products that are vapor open to the exterior ensure that if moisture does condense inside the wall it will dry to the outside, rather than remaining trapped. That mitigates the risk of mold and mildew and is indicated by a product’s perm (permeability) rating. Therefore, you want CI materials with a high perm rating. Note also, that moisture within our walls generally dries to the outside more readily in heating climates – climates where the heat load is greater than the cooling load.

Thick insulation: CI is essentially the down in a down jacket – for your home. A thicker insulation layer will move the dew point—the point where moisture in the air condenses into water—outside of the wall assembly. All things equal, the higher the R-value, the less condensation will occur within the wall assembly itself. Instead, it will occur towards the exterior surface and within the CI layer – and ideally where there is no food source for mold.

Please note that we aren’t talking about Passive House standard here—we’re talking about an extra couple of inches of vapor-open insulation. Over a building’s lifespan, continuous insulation is highly cost-effective because it reduces energy bills and the risk of defects. It also improves occupants’ level of comfort.

Implementation

Having made the case for continuous insulation, we’ll delve into materials and methods.

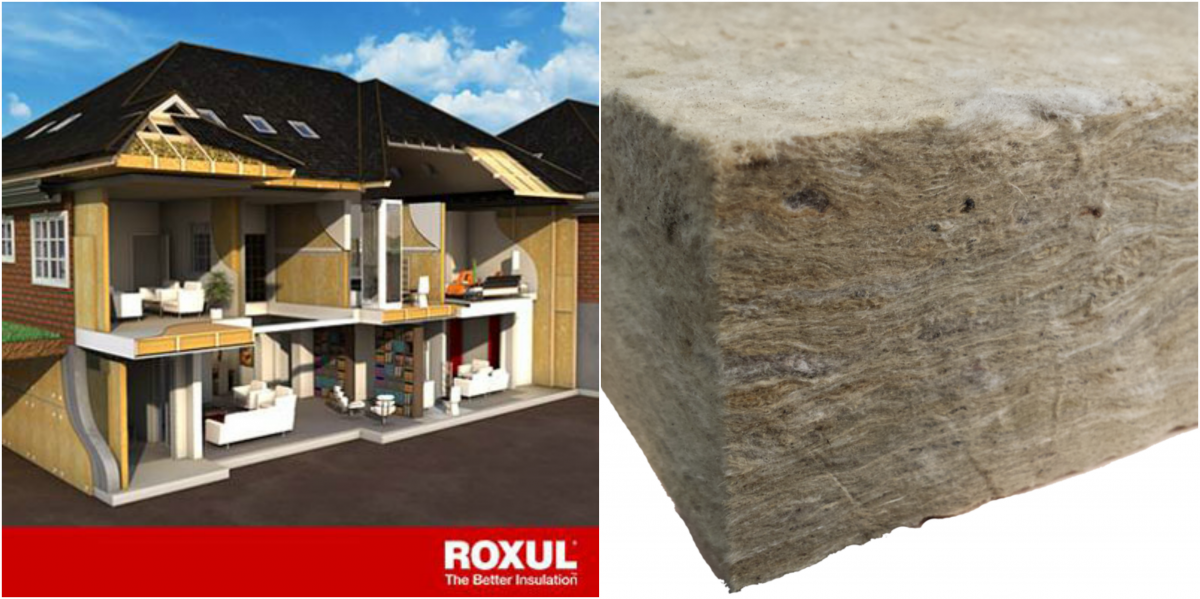

- Materials—insulation. We tend to recommend rigid mineral wool insulation because it’s vapor open, highly permeable, inflammable, contains no food source and is well-suited to Colorado’s climate. Mineral wool is, in a word, robust. Mineral wool products by ROXUL, recently rebranded to ROCKWOOL, for instance, outperform foam insulation in terms of vapor permeability and sound attenuation. It’s also a fire retardant with no flash point and melts at 2150 degrees (House fires burn at a range of 1200 – 1400-degrees).

Placement. CI is generally applied to the exterior of a building envelope. In most cases, exterior application is easier and more effective than an interior CI strategy. It helps move the dew point outside the wall assembly and it doesn’t require the detail work of fitting it to joists and other structures.

Foams generally have extremely low perm ratings, meaning they do not allow moisture to migrate through the material. By contrast, mineral wool is very permeable (vapor open). It enables moisture to pass through like a good pair of wool hiking socks. Also, it is made of “rock” and there is no food source in Rockwool preventing mold from growing.

Finally, mineral wool is more environmentally friendly than foam insulation because it requires few virgin materials to manufacture. Roxul Rockwool is made from 85 percent recycled slag from steel processing and 15 percent raw basalt.

- Materials—air/weather barriers. A good, vapor open air/weather barrier is essentially Gortex for your house because it helps keep both moisture and air out of your wall. (e.g., it keeps the rain out and allows “sweat” to dry). There are a variety of products available.

- If you’re doing a deep energy retrofit, you’ll want to replace felt paper with Majvest or another air/weather barrier with a high perm rating (Majvest’s perm rating is 68). Add CI when feasible (you may be surprised how often this is the case) and tape all Majvest seams to prevent air infiltration.

- New builds. The best approach for a new home is to use continuous insulation, air sealing and high-performance windows for an all-around robust envelope.

We recommend thick, well-insulated walls to reduce heat transfer, which in turn reduces condensation, as previously noted. Apply mineral wool CI products such as ROCKWOOL Comfort Board 80 or Comfort Board 110.

In short, continuous insulation makes code compliance easier, improves building comfort, reduces defects and results in more resilient, longer lasting homes. It’s a great approach for retrofits as well as new builds.

P.S. – For a fascinating demonstration of how ROCKWOOL mineral wool’s fire and heat resistance, check out this 90-second video. We don’t want to give too much away, but it involves chocolate.