Furnace Retrofit for All-Around Comfort

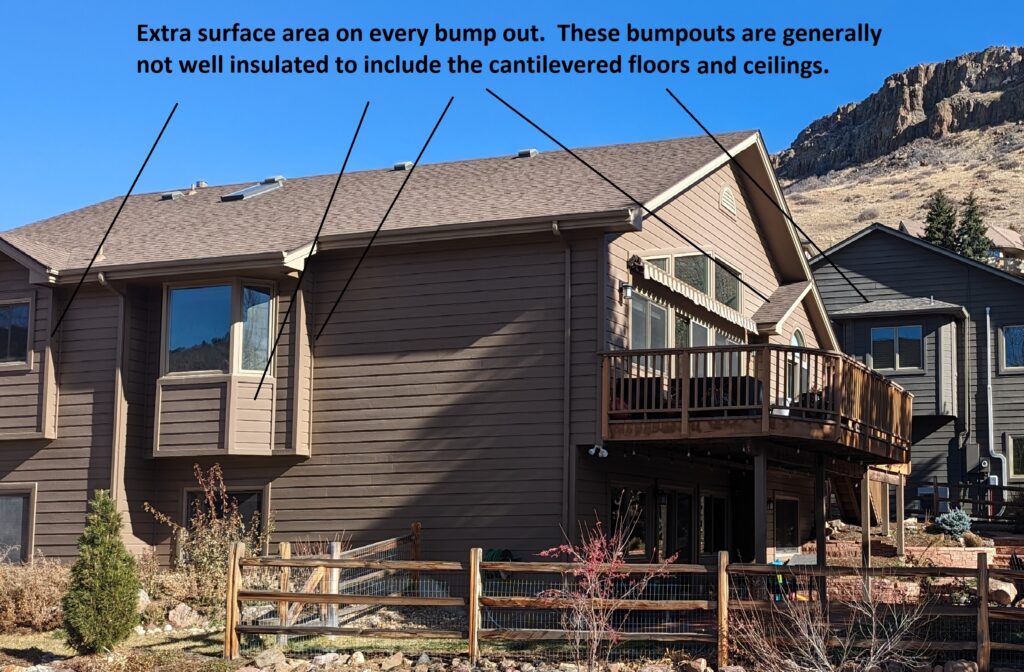

Welcome back to the Collins/Ruddy Residence, where our very own Todd Collins and his family have been overhauling their entire tri-level home! Some of us have the opportunity to build our dream home from scratch and give it all the sustainable features we want. But for most, we find ourselves retrofitting an older home that may have other less-sustainable features and designs than we might have chosen if building a new house. That’s exactly where Todd and his family found themselves in the home they love in Golden, Colorado.

They’ve done a ton to the house already, from improving insulation, installing more efficient windows and doors, and breaking from their reliance on natural gas. Today, we dive into how they’ve retrofitted their furnace and how they heat their home.

The Big Switch!

The Collins/Ruddy Residence replaced the furnace with a Mitsubishi heat pump condenser and whole-house indoor air handler, which allowed them to use their existing ducting for the most part while also going electric. As part of this new setup, they placed the exterior compressor on the south side of the home to increase efficiency in the warmer parts of the day. They also went with an electric heat pump, eliminating their need for natural gas. They went with a 36 kBTU unit which allows for variable speed and it runs as hard as it needs to. As a result of this new setup, the house also required some new ducting in the family room to eliminate(disconnect) sub-slab ineffective ducts.

The Collins/Ruddy Family worked with Bill Lucas to help them with this new setup and installation. That is partially because Bill is big on recycling as many of the older unit components as possible to prevent them from going into a landfill.

Improved Air Filters

Traditional furnace filters are generally 1” thick MERV 8. Todd and his family went with a MERV 11 filter to improve their indoor air quality (IAQ), which has more of a curtain style shape and is 4” thick. These don’t need to be changed as frequently as the traditional smaller filters and provide greater filtration without impacting air flow as some standard sized (1”) high MERV filters do.

Benefits All Around:

- Improved Air Quality: With this new heat pump, they can leverage a more efficient air filter, increasing their indoor air quality and efficiency of their unit.

- Electric-Only, allowing for more sustainable energy sources and lower energy bills. This will also help the homeowner go Net Zero in the future.

- Sound! The new internal heat pump is extremely quiet where all you can hear is the air flowing compared to a traditional fan/motor that was noisy whenever it was operating.

- Air Conditioning: This new unit includes both air conditioning and heat in one device, meaning that the family could get rid of the older traditional air conditioning unit that had sat near their patio. Now on a summer day, they can enjoy their quiet patio instead of hearing the noisy air conditioning unit.

Limitations

- Time: Due to the variable speed on the unit, it doesn’t go into the highest fan speed often. Instead, it runs at a lower level to heat the house and as a result, it can take a little longer to get the house up to the desired temperature.

- Different: You might be thinking this all sounds different from anything you’ve ever seen in a house visit or home inspection. Very few homes pursue this kind of transformation to where you’re ready to ask your gas company to permanently cap the meter. As a result, sometimes you come across scenarios where contractors don’t understand what you’re doing, or even energy companies don’t understand what you’re doing. For example, Xcel Energy still charges a “connection fee” until you officially cap off the connection to the meter. There are small things to ask questions around when you’re working with third parties like energy companies. Since you’re going a little off the beaten path, you have to be an advocate for yourself in the project.

The switch to this Mitsubishi whole-house heat pump has been a game-changing move for the Collins/Ruddy family. It’s allowed them to achieve their goal of capping their gas connection to the entire house, while also improving air quality. Retrofitting a home is never an easy task, but it can be extremely rewarding when you see the amazing benefits and overall performance that accompany decisions like these!