Just like the dinosaurs, fossil fuels are going extinct in some communities! We’ve heard it mentioned for years, but many communities are starting to put policies in place to actually reduce the reliance on fossil fuels. Fossil fuel bans are showing up more and more in municipalities and communities around the United States and creating quite the buzz!

The Fossil Fuel Ban Trend

Cities like Boston and Berkeley, have been more prominent in the news with new building codes to reduce natural gas infrastructure and the associated greenhouse gas emissions that come with fossil fuels. The city of Golden, Colorado is also actively building out new code regulations to reduce the reliance on fossil fuels to operate buildings.

We’re also seeing sustainable communities on the rise where homeowners actively seek out a net-zero lifestyle. One example of this is the Geos Neighborhood in Arvada where the houses are built with net-zero energy. They are built to take advantage of solar energy, geothermal energy, and even goat energy (weed control!). They’ve shown that it can be done and done in a way that doesn’t hike up construction costs.

The Challenge

Any change like this is set to ruffle a few feathers from those who are used to doing things the fossil fuel way. The shift toward sustainable industries has always received a fair amount of pushback from those in the fossil fuel industry, as well as those who simply don’t want a change.

But there are some very real concerns with changing the game for building codes. First, in any of these towns and cities, you are faced with a transition and not a clean switch. You have decades of buildings running off of fossil fuels, so you have to account for the transition where you have both fossil fuels operating as well as cleaner energy, like electric, operating in the same neighborhood – a situation found nearly everywhere. Secondly, many land-locked towns that are largely developed already, like Golden, struggle with solar access. Many towns the size of Golden also struggle with the costs of making a change like this on a large scale.

Then, you encounter scenarios where fossil fuels still are a dominant need. Noting that Todd Collins is not a spokesperson for the City of Golden or the City’s Sustainability Board, Todd shares about Golden’s Sustainability Board’s assessment: “We also knew there were industrial, or process energy, situations that posed difficulties. So, we focused our attention on the buildings’ energy consumption- where energy is being used to operate the buildings (including lighting, plug loads, water heating, heating and cooling, etc.).” As a result, Golden is considering a more focused, prescriptive approach while getting immense buy-in from the community and industry experts. Making these types of policy changes is a fairly significant process.

It’s not a cut-and-dry answer to switching away from fossil fuels.

The Opportunity:

It’s clear there is an interest by a large portion of homeowners, and there is also a shift in local policy to transition to electrification and away from fossil fuels. It’s also clear that the way to get there is not always simple and easy.

What’s fun is to see that it IS possible! Seeing communities like Geos Neighborhood pop up and new code requirements arise means we’ll see these norms change. Sustainable solutions will become the standard instead of the exception. It’s an exciting time to be part of change!

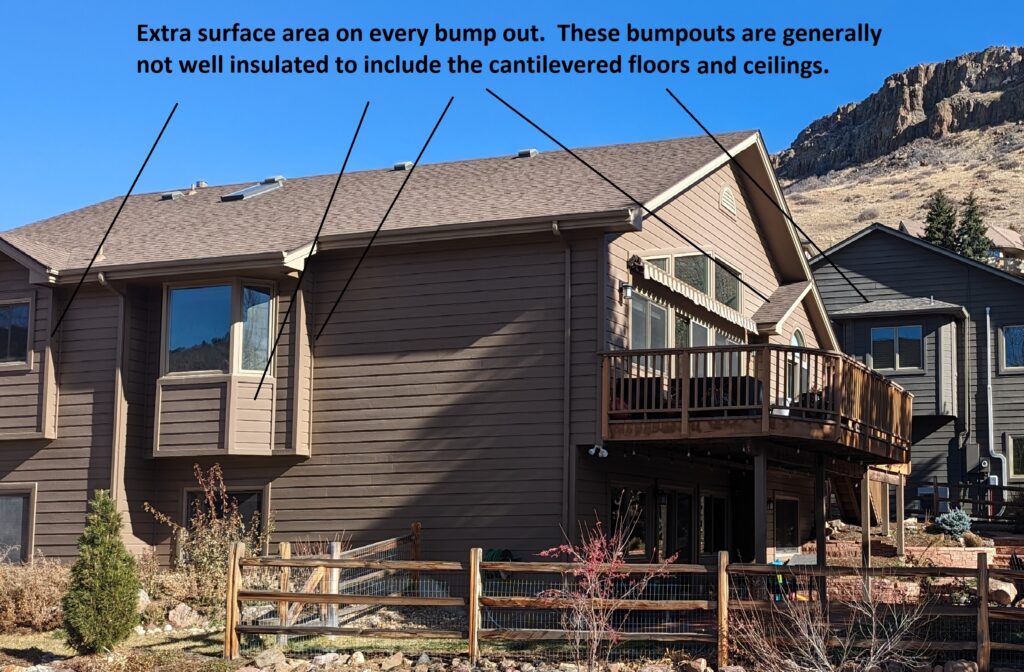

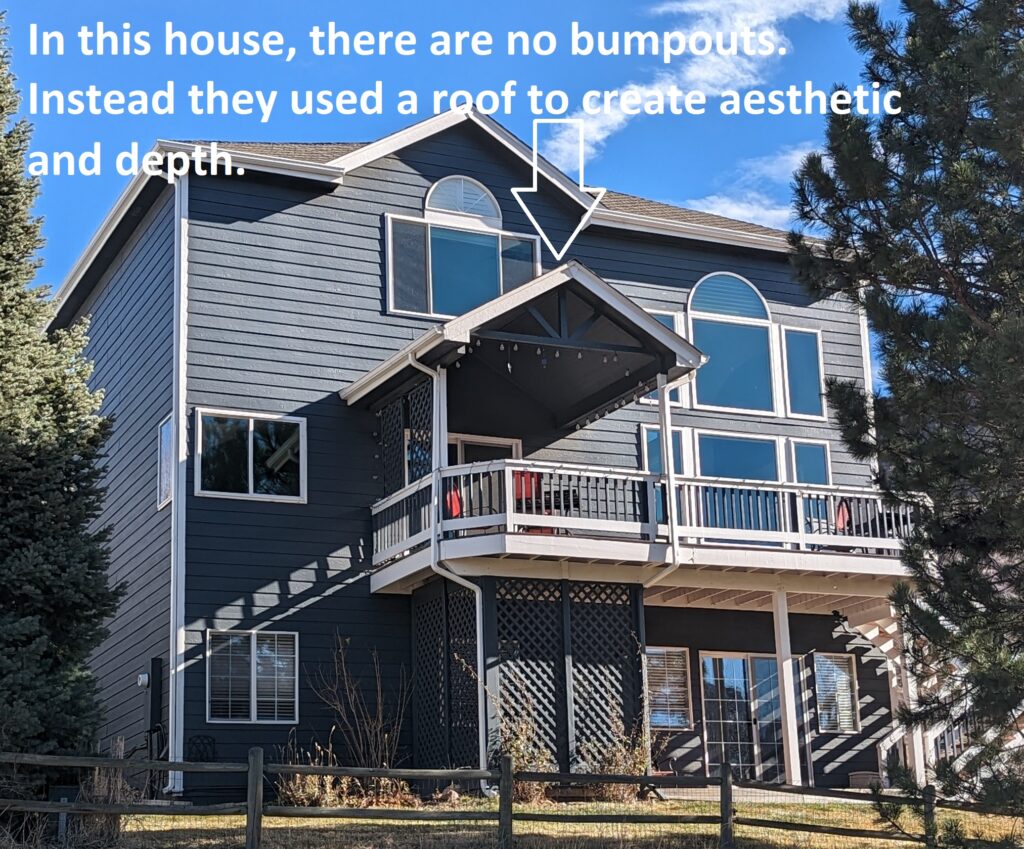

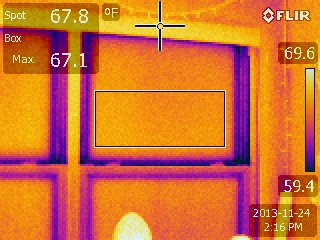

As electrification becomes more dominant, high performance becomes a must! We no longer can settle for the inferior construction approaches we’ve put up with for years. Instead, we know that high-performance design, workmanship, materials, and products actually save us in the long run. All of these new code trends have increased the demand on high-performance construction products, especially with windows, doors, and insulation. These and a solid attention to details make a big difference!

Three Simple Things You Can Do:

You may not live in a community where fossil fuel bans are in place, but you can still do your part as a homeowner to reduce your load on fossil fuels.

- Purchase energy-efficient appliances. Make a sustainable choice at your next appliance purchase, or consider upgrading sooner.

- Go solar. We live in a sunny state making solar panels an easy way to move toward electrification.

- Efficient windows. Make a smart choice when you purchase your windows and doors. Energy-efficiency matters here and can go a long way to reduce your heating and cooling costs, which as a result, reduces your fossil fuel consumption. Your energy bills each month will also thank you!

Not sure where to start? Our team can help point you in the right direction. Whether you’re building from scratch or retrofitting your home, you can easily reduce your own fossil fuel load with a few simple choices for your home!